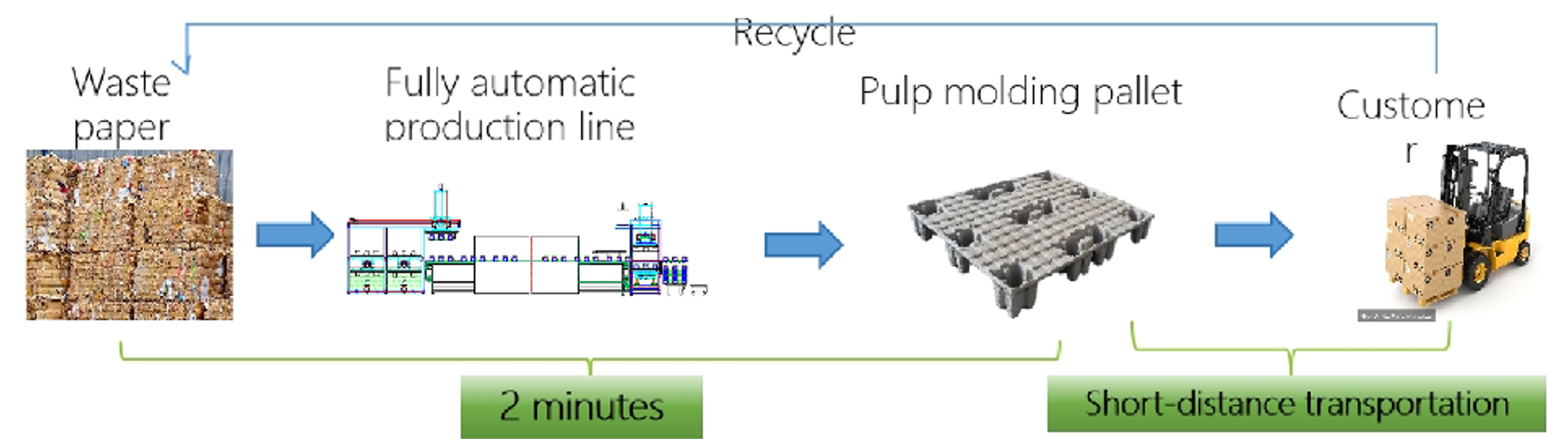

75% Lower Cost, 100% More Sustainable: Revolutionizing the $100 Billion Pallet Industry

FibroCorp is pioneering the next generation of sustainable logistics solutions through innovative pulp molding technology. Based in Tacoma, Washington, we’ve developed patented processes that transform waste paper into high-performance products that outperform traditional alternatives both economically and environmentally.

With over 20 years of technical expertise and multiple international patents, our team is poised to revolutionize the $100+ billion global pallet industry while making a significant contribution to environmental sustainability.

Our Revolutionary Pulp Pallet Technology

FibroCorp’s breakthrough innovation challenges what’s possible in the pallet industry. Our patented pulp molding technology transforms low-grade waste paper into high-performance pallets with remarkable properties:

- Dynamic load capacity of 2.5-5 tons

- Static load capacity up to 10 tons

- 75% cost reduction compared to wooden pallets

- 100% recyclable through standard waste paper channels

- Zero tree harvesting required

- Pollution-free manufacturing process

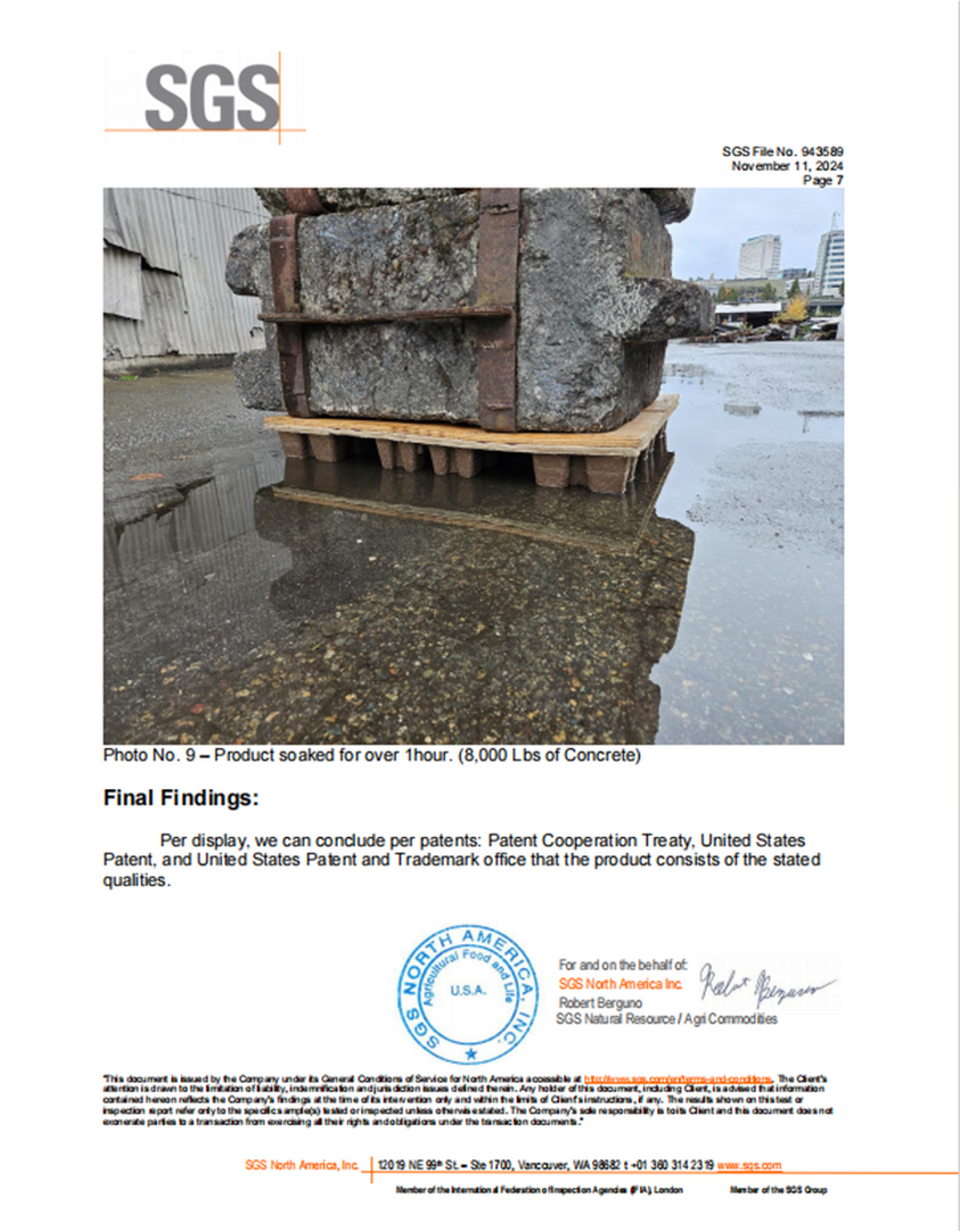

Certified by SGS international standards, our pulp pallets represent a fundamental shift in logistics sustainability.

Global Validation & Recognition

SGS, the world’s leading inspection, verification, testing and certification company, has validated our pulp pallet technology across multiple performance parameters. This independent certification demonstrates that our revolutionary approach meets or exceeds industry standards for load capacity, durability, and environmental performance.

Environmental Leadership

At FibroCorp, we’re committed to environmental sustainability through innovative technology. Our pulp pallet solution offers remarkable ecological benefits:

- Conserves forest resources by eliminating tree harvesting

- Reduces carbon emissions by utilizing waste paper

- Decreases landfill volume through circular economy principles

- Minimizes water usage in manufacturing processes Our technology has the potential to save 488 million trees annually while reducing global carbon emissions by 250 million tons.